Benefits of Testing Online and in High-Speed Balance Pits

Generatortech Rotor Winding Shorted Turn Flux Probe testing is the most comprehensive testing that can be performed on your generator. When performing online testing, the rotor is at is rated speed and temperature, both of which can impact the shorted turn condition of the rotor winding.

Without a flux probe, your rotor winding will need to be tested at standstill or will need to be pulled from the stator to be tested in a high-speed balance pit (spin pit). Standstill testing will miss turn shorts that are either temperature- or speed-dependent.

Generatortech equipment is used in high-speed balance pits around the world and testing at various speeds and rotor temperatures have repeatedly proven the existence of both speed- and temperature-dependent turn shorts. The images below present three case studies from flux probe testing in service companies’ high-speed balance pits. The rotors displayed speed- and temperature-dependent turn shorts.

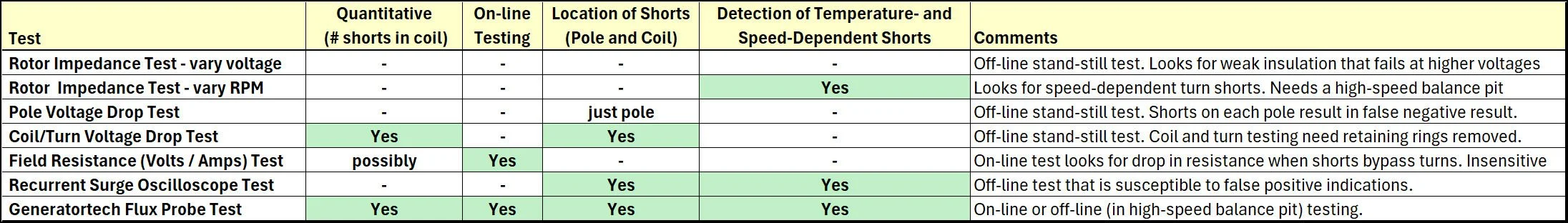

A number of standstill tests are used to check the rotor winding condition during outages and rewinds. Each has their strengths and weaknesses. The table below displays a comparison of different rotor winding tests.

Case 1A - High Speed Balance Pit Flux Probe Test

In balancing pits, flux probe data is often recorded at different rotor speeds. In this example, at 1250 RPM, the rotor was free of turn shorts. At this speed, the compressive force on the coil stacks was not enough to develop any shorts.

Case 1 B- High Speed Balance Pit Flux Probe Test

At 3600 RPM, three speed-dependent turn shorts were detected. Each turn short developed at a different rotor speed. Tests performed at stand-still would miss these three shorts. All three speed-dependent shorts were fixed before the rotor was shipped.

Case 2 - High Speed Balance Pit - Running Impedance and Flux Probe Tests

A 60-Hz AC running impedance test showed a short developing as rotor speed rose above 2800-RPM and then clearing when the speed dropped below about 2200-RPM. A spin-pit flux probe test showed the speed-dependent short was located in Coil 8B. The short in Coil 8B was fixed before the rotor was shipped.

Case 3A - High Speed Balance Pit Flux Probe Test

At 3000 RPM, the rotor winding was free of turn shorts.

Case 3B - High Speed Balance Pit Flux Probe Test

At 3600 RPM, the rotor developed a speed-dependent short in Coil 6A

Case 3C - High Speed Balance Pit Flux Probe Test

After a heat run where the rotor winding was raised to 150 F, the rotor winding developed a temperature-dependent short in Coil 7A when running at 3600-RPM. The Coil 7A short was most likely due to the thermal expansion of the turns . The speed-dependent short in Coil 6A was also detected again.