Case Studies

Generatortech, Inc. has extensive experience in analyzing rotor winding shorted turns. Since 1989, over 4000 Generatortech flux probes have been installed in generators worldwide. We have a large and growing database of test data on these units. Many generators with shorted turns detected using our equipment have been taken apart during this time period and we have been gratified to have had our shorted turn predictions verifed.

This section provides a look at a few case studies that forcefully make the case for flux probe monitoring of your rotors. If you are responsible for making maintainance decisions for your generator sets, you owe it to yourself to arm yourself with the only tool that can quickly and accurately assess the condition of your rotor's insulation system before coming off-line.

While off-line tests are valuable, they can not detect speed-dependent shorted turns (shorts that only develop when the rotor is at rated speed). Tests in balance-pits, with our equipment, has confirmed the presence of speed-dependent shorted turns in a number of cases. These tests allowed the service companies to repair the speed-dependent shorted turns at their facility before shipping the rotors back to their customers, saving enormous time and expense.

===========================================Case 1:

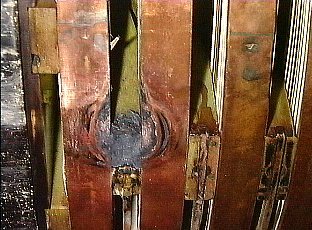

Coils 6 and 7 Completely Shorted Out of Two-Pole Rotor

This case presents a two-pole rotor with 7 coils/pole that has two coils completely shorted out of the field winding circuit. The top turns of coils 6 and 7 on one pole initially formed a partial short across a blocking wedge that created enough heat to burn through the retaining ring insulation and allowed the top turns of coil 6 and 7 to form a short through the retaining ring itself (see photo).

Waveform shows both Coils 6 and 7 completely shorted out of Pole A

===========================================Single Turn Short in a Four-Pole Rotor

This case presents a four-pole rotor with a single turn short. The shorted turn is in Coil 2 of Pole B. Coil 2 has seven total turns, so 1 turn short represents a 14% decrease in amp-turns produced by this coil. The shorted turn is obvious in the waveform (below) and the quantative analysis indicated one turn short in Coil 2-Pole B. A turn-drop test performed when the rotor was pulled from the generator confirmed that a short existed between the second and third turns of Coil 2 in Pole B. Since the generator was able to maintain full load even with this shorted turn condition, no repairs were made at that time, despite the recommendation of the OEM. This decision was made, in part, because of the ability to monitor the shorted turn condition of the rotor while the unit remained on-line using Generatortech's flux probe and analysis equipment. This case illustrates the cost-savings that can be realized when unnecessary repairs can be eliminated or deferred by relying on accurate shorted turn monitoring equipment.

Four Pole Example - One turn short in Pole B - Coil 2

- GENERATORTECH, INC.

- Support@Generatortech.com

- Phone: 518.399.4646

- Fax: 518.399.7562

- 104 Newman Rd

- Schenectady, NY USA 12302-9517

© 2017 Generatortech, Inc.